|

| ADVANTAGES of SK 1400 B PRESSURE SANDBLASTING MACHINE |

SK 1400 B Pressure Sandblasting Machine has the feature of special pressure system allows the sand to be sprayed at higher speeds and providing more pieces to be processed. 3 times more performance than its counterparts. While 10 parts that other machines in processing the material per unit time SK 1400 B process 30 parts at that time. All our manufacturing is designed as three-dimensional including center-of-gravity measurements. Operating dustless by means of custom made filter. Jet pulse system filter clean itself automatically. This blasting cabinet is safer by door switches, solenoid valve and custom made panel. Cabinet Dimensions are 1400 x 1000 x 1000(h) mm.

***SANDBLASTING ABRASIVES USED IN SAYKAR PRESSURE SANDBLASTING MACHINES:

*Aluminum Oxide,

*Glass Bead,

*Garnet,

*Silicon Carbide,

*Ceramic Bead,

*Glass Sand,

*Basalt,

*Blasting Soda,

*Plastic Abrasive,

*Steel Shot,

*Steel Grit,

*Stainless Steel Grit,

*Stainless Steel Shot.

Saykar pressure sandblasting machines are used safely in many companies worldwide. For example: Italy, Spain, Germany, France, Bulgaria, Slovakia, Kosovo, Iran, Kuwait, Egypt, Jordan, Iraq, Azerbaijan, Georgia, UAE.

Longer service life, less maintenance times, process safety, fast service and technical information support are also among the advantages we can offer you. We do not only produce sandblasting machines, we pay great attention to the production process of our customers and the smooth functioning of our machines.

|

| ***Our company is the most preferred sandblasting machine manufacturer in Turkey*** |

|

CE |

|

|

| ADVANTAGES of SK 1600 B PRESSURE SANDBLASTING MACHINE |

SK 1600B Double Operator Pressure Sandblasting Machine; has a compact design with filter system and produced for sandblasting up to 150cm parts. It is high pressure type sandblasting machine suitable for general purpose sandblasting processes. It is a self-cleaning eco-friendly machine with Jet Pulse filter system. Sandblasting pressure and abrasive quantity can be adjusted. This machine is ideal for difficult surfaces that require high power such as rim, marble, teflon

pan and casting. SK 1600 B is a pressure sandblasting machine which has double operator working possibility.

*High Blasting Power with Pressure System

*High Processing Capacity

*Compact Design and Original Working Principle

*JET-PULSE Filter System

*Adjustable Fan Suction Power

*PLC Control 7" Touch Screen

*High Working Safety

*Sand and Dust Cyclone Separation Feature.

SK 1600 B Pressure Sandblasting Machine, Saykar design, has high processing capacity, especially in the sandblasting works that require power, as well as the ability to perform fast cleaning and coating removal can be done four times faster than injection type machines. This pressure sandblasting machine with its wide cabin dimensions can be used for surface preparation processes before coating and can be used to remove the coatings on the surfaces of faulty products. Cabinet Dimensions are 1600 x 1600 x 1000(h) mm. One of the most important feature of SK 1600 is double operator working availability.

|

|

|

| ADVANTAGES of SK 2600 B PRESSURE SANDBLASTING MACHINE |

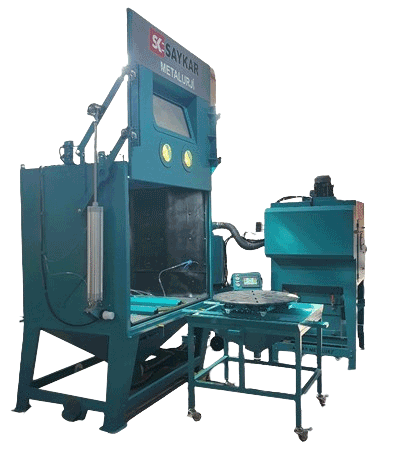

| SK 2600 B Pressure Sandblasting Machine consists of Cyclone System, Filtration Unit and Automatic Turntable System. This machine, designed for sandblasting heavy and large parts, is equipped with various safety mechanisms. SK 2600 B Pressure Sandblasting Machine is one of Saykar's latest machines, with its cabin and automatic table design that allows sandblasting of parts with a weight of 1000 kg, length of 2500 mm x 1500 mm and a height of 1700 mm in limit dimensions. With its pressurized system feature, which is only found in Pressure Sandblasting Machines, it allows sand to be sprayed at higher speeds, thus allowing faster part sandblasting. |

|

|

|

| FEATURES AND ADVANTAGES OF SK 1450 OK B PRESSURE SANDBLASTING MACHINE |

| SK 1450 OK B Front Cover Pressure Sandblasting Machine consists of Cyclone Pressure Pot System, Filtration Unit, Manual Spraying and Manual Rotary Table and Stand Unit and Automatic Front Cover System. Equipped with a pressure spray system, the machine can only be used manually. The machine is designed to load heavy parts from the front.

The front cover of the machine opens and closes automatically with 2 pneumatic pistons. In order not to pose a risk to the operator when opening/closing the front cover of the machine, the operator must have both hands pressing the buttons on the control panel while opening the machine cover.

With this application, the operator is never likely to be trapped between the door and the machine, such as the door falling or the pneumatic hoses bursting. The absence of a second personnel around the machine should be under the operator's control.

SK 1450 OK B Front Cover Pressure Sandblasting Machine, with its cabin and table design that allows sandblasting of parts with limit dimensions of 1450 mm length It allows. |

|

| | | |