|

|

SK 1480 C OTM DT AUTOMATIC TURNTABLE PRESSURE SANDBLASTING MACHINE FEATURES AND ADVANTAGES |

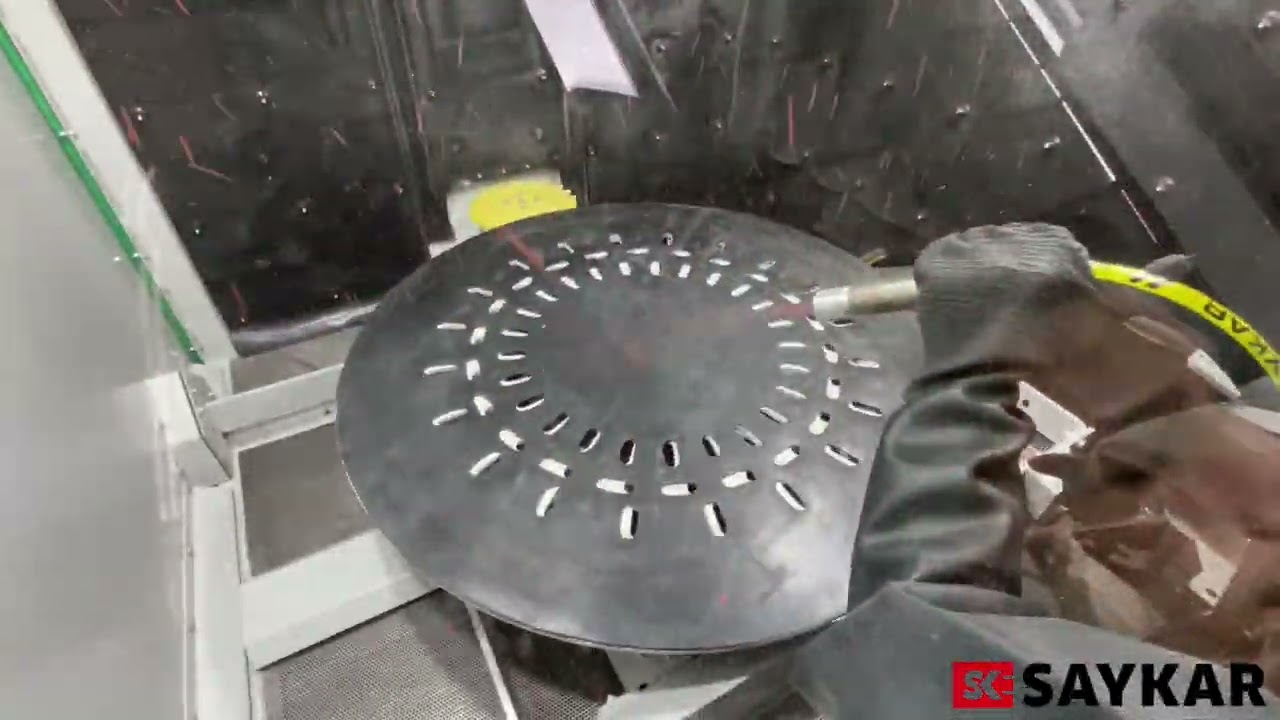

SK 1480 C OTM DT Automatic Turntable Pressure Sandblasting Machine stands out with its compact design and space-saving advantage for surface treatment processes requiring high surface roughness or high blasting power (such as rubber coating, Teflon coating removal, enamel removal, wheel cleaning). The rotary table in this machine has a diameter of Ø990 mm and a thickness of 8 mm, with a carrying capacity of 1000 kg and 6 support and balance wheels to evenly distribute the load.

It allows parts to be loaded onto the rotating table using various lifting equipment such as overhead cranes or forklifts and automatically fed into the machine.

The Filter Unit's Jet-Pulse system collects the accumulated dust on itself and stores it in the waste section of the dust collection unit at regular intervals. After connecting the filtration system to the exhaust, it operates at a noise level below 75 dBA.

This pressure sandblasting machine, which can be produced in right or left orientation and equipped with automatic rotary table and guillotine cover features, offers up to 4 times faster and more powerful processing compared to standard sandblasting machines. We can also produce specially designed, fully automatic solutions for standard parts.

|

***Our company is the Turkey's most preferred Sandblasting Machine Manufacturer***

|

|

CE |

|

We offer dust-free working opportunities with our machines supported by the Jet-Pulse filter system. Operator safety and cleanliness of the working environment are among the issues we always prioritize.

SK 1480 C OTM DT Automatic Rotating Pressure Sandblasting Machine makes the process easier with its Automatic Rotating Table unit. It can be used in automatic mode at a fixed RPM or automatically in the desired direction through the foot pedals on the touchscreen.

We aim to meet your pressure sandblasting machine needs in this segment while occupying less space.

Pressure Sandblasting Machine's Technical Specifications:

Pressure System,

Nozzle Hanger apparatus allowing two-handed operation,

Jet Pulse filtration system,

Automatic Turnable Entry-Exit System,

Automatic Rotary Table Motion System,

Safety Package

Pressure Sandblasting Machine's Advantages:

*High Spraying Pressure

*Low Dust Emission (Test report available for dust dispersion)

*Up to 4 times faster processing compared to vacuum systems

*Loading convenience with Overhead Crane

*User-friendly operation with PLC Screen

*Easy maintenance with cyclone maintenance cap

Please feel free to contact us for any assistance or information you may need. Our staff is here to assist you in the best way possible.

"Saykar Total Number of Sandblasting Machines 1723"

"Wet Blasting Machines 187"

"Sandblasting Machines Exported Abroad 141"

|

|

|

SK 2018 C OTM DT AUTOMATIC TURNTABLE PRESSURE SANDBLASTING MACHINE FEATURES AND ADVANTAGES |

SK 2018 C OTM DT Automatic Turntable Pressure Sandblasting Machine stands out with its high sandblasting power and surface treatments of heavy parts. The turntable in this machine has a diameter of Ø1500 mm, a carrying capacity of 1000 kg and 10 support balance wheels, allowing the load to be carried evenly.

It allows the parts to be loaded onto the turntable with various lifting equipment such as overhead cranes or forklifts and placed into the machine automatically.

Filter Unit Jet-Pulse is an automatic and powerful system. The filtration system operates under 75 dBA noise level after the chimney connection is made.

This pressure sandblasting machine, which can be produced in right or left orientation and equipped with automatic rotary table and guillotine cover features, offers up to 4 times faster and more powerful processing compared to standard sandblasting machines. Upon demand, specially designed sandblasting machines with desired features are also produced. |

"Let Us Welcome You in Istanbul, Explore Our Sandblasting Machines, Visit Our Showroom and Decide with Confidence. See Our Machines For Yourself"

CE

|

We offer dust-free working opportunities thanks to our system supported by the Jet-Pulse filter. We always prioritize the safety of our customers and the cleanliness of the working environment.

SK 2018 C OTM DT Pressure Sandblasting Machine with Automatic Rotary Table makes it easier to use during the process thanks to its Automatic Rotary Table unit. It can be used automatically in automatic mode at constant RPM via the touch screen or in the desired direction via foot pedals.

Pressure Sandblasting Machine Technical Specifications:

Pressurized System,

Nozzle Hanger apparatus that allows two-handed operation,

Filtration System with Jet Pulse feature,

Automatic Rotary Table Entry and Exit System,

Automatic Rotary Table Movement System,

Safety/Security Package

Advantages of Pressure Sandblasting Machine:

*High Spray Pressure

*Low Dust Emission (Dust emission Test report is available)

* Opportunity to work 4 times faster per unit time compared to vacuum systems

*Ease of Loading with Ceiling Crane

*Easy to use with PLC Screen

*Ease of maintenance with maintenance cover on the cyclone

|

|

| |