STEEL SHOT BLASTING MEDIA |

|

Steel Shot which is separated as martensitic and bainitic, is used of steel and cast iron sandblasting. Steel shot can be used at the air and turbine system sandblasting machines. It is more economical when compared to other blasting medias, evaluating the number of reuse. These materials have a lifetime upto 100 hits. Bainitic steel shot's reuse time is more than the martensitic steel shot. It is sensitive to moisture and corrosion may happen. For this reason, the steel shots sold at bags with holes will rust in a short time. Rust causes rapid wear on turbine blades during use. Sold or bought steel shots should be considered to be rust-free. |

STEEL SHOT PHYSICAL CHARACTERISTICS |

| Steel Shot - Specific Gravity |

7,2 g/cm3 |

| Steel Shot - Average Bulk Density |

5,9 g/cm3 |

| Steel Shot's Hardness |

40-52 HRC |

| Steel Shot's Crystal Shape |

Martensitic |

| Steel Shot's Durability |

High |

| Steel Shot's Free Flow Feature |

97 % minimum |

| Steel Shot's Sensitivity To Acid |

No |

| Steel Shot's Moisture Absorption |

No (Not hygroscopic) |

| Steel Shot's Magnetic Characteristic |

High |

| Steel Shot's Transmission of Electricity |

High |

| Steel Shot's Radioactivity Characteristic |

Not Been Determined |

| Steel Shot's Pathological Damage Characteristic |

No |

| Steel Shot's Free Silica Content |

No |

STEEL SHOT CHEMICAL CHARACTERISTICS |

| Carbon |

0,85-1,20 % |

| Manganese |

0,60-120 % |

| Silisium |

0,40 % minimum |

| Sulphur |

0,05 % maximum |

| Phosphor |

0,05 % maximum |

STEEL SHOT BLASTING MEDIA SIZES |

| S-70 |

0,20 mm blasting media particles |

| S-110 |

0,30 mm blasting media particles |

| S-170 |

0,42 mm blasting media particles |

| S-230 |

0,60 mm blasting media particles |

| S-280 |

0,71 mm blasting media particles |

| S-330 |

0,84 mm blasting media particles |

| S-390 |

1,00 mm blasting media particles |

| S-460 |

1,19 mm blasting media particles |

| S-550 |

1,41 mm blasting media particles |

| S-660 |

1,68 mm blasting media particles |

| S-780 |

2,00 mm blasting media particles |

STEEL SHOT BLASTING MEDIA - AREAS OF USE |

| BRANCH OF INDUSTRY |

STEEL SHOT SIZES USED |

REASON OF USAGE |

| Casting Industry |

Steel Shot S-780 ve S-660 |

Steel sandblasting, large nodular iron casting parts cleaning |

| Casting Industry |

Steel Shot S-550,S-460,S-390,S-330 |

Steel sandblasting, medium nodular iron casting parts cleaning |

| Casting Industry |

Steel Shot S-280,S-230,S-170,S-110 |

Non-ferrous cast parts cleaning |

| Hand Tools Manufacturing Industry |

Steel Shot S-280,S-230,S-170 |

Hand tools cleaning before coating |

| Fitting Manufacturing Industry |

Steel Shot S-390,S-330,S-280 |

Fitting manufactures cleaning before coating |

| Shipbuilding Industry |

Steel Shot S-550,S-460,S-390,S-330 |

Shipbuilding Industry steel sandblasting operations |

| Spring Manufacturing Industry |

Steel Shot S-460,S-390,S-330,S-280 |

For the purpose of stress relief |

| Casting Industry |

Steel Shot S-70 |

Recuperator cleaning |

| Steel Manufacturing Industry |

Steel Shot S-550,S-460,S-390,S-330 |

For the purpose of stress relief of all steel materials, At steel sandblasting machines |

STEEL GRIT BLASTING MEDIA |

|

Martensitic steel grit is obtained by grinding hardened steel shots of martensite structure and more suitable to be used at air sandblasting system. Due to its structure this blasting media damages the turbine wings very quickly and gives harm to turbine system sandblasting machines. Steel grit is used mainly for the purpose of removing dirt and rust from the surface quickly and roughening prior to painting. It's reusing time is shorter than the steel shot. However, considering the processing speed, steel grit is much faster than steel shot at providing surface cleaning. For this reason steel grit is more economical. It is sensitive to moisture like steel shot and same cautions should be considered. You can reach the technical information about steel shot, steel grit and everything about sandblasting at our company!!! |

STEEL GRIT PHYSICAL CHARACTERISTICS |

| Steel Grit - Specific Gravity |

7,2 g/cm3 |

| Steel Grit - Average Bulk Density |

5,9 g/cm3 |

| Steel Grit's Hardness |

40-52 HRC |

| Steel Grit's Crystal Shape |

Martensitic |

| Steel Grit's Durability |

High |

| Steel Grit's Free Flow Feature |

97 % minimum |

| Steel Grit's Sensitivity To Acid |

No |

| Steel Grit's Moisture Absorption |

No (Not hygroscopic) |

| Steel Grit's Magnetic Characteristic |

High |

| Steel Grit's Transmission of Electricity |

High |

| Steel Grit's Radioactivity Characteristic |

Not Been Determined |

| Steel Grit's Pathological Damage Characteristic |

No |

| Steel Grit's Free Silica Content |

No |

STEEL GRIT CHEMICAL CHARACTERISTICS |

| Carbon |

0,85-1,20 % |

| Manganese |

0,60-120 % |

| Silisium |

0,40 % minimum |

| Sulphur |

0,05 % maximum |

| Phosphor |

0,05 % maximum |

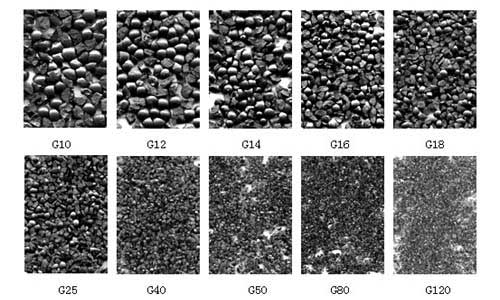

STEEL GRIT BLASTING MEDIA SIZES |

| G-10 |

2,00 mm blasting media particles |

| G-12 |

1,70 mm blasting media particles |

| G-14 |

1,41 mm blasting media particles |

| G-16 |

1,19 mm blasting media particles |

| G-18 |

1,00 mm blasting media particles |

| G-25 |

0,71 mm blasting media particles |

| G-40 |

0,42 mm blasting media particles |

| G-50 |

0,30 mm blasting media particles |

| G-80 |

0,20 mm blasting media particles |

| G-120 |

0,12 mm blasting media particles |

STEEL GRIT BLASTING MEDIA - AREAS OF USE |

Dam Maintenance And Repair Industry |

Steel Grit G-14,G-18,G-25 |

Dam's pipelines cleaning process before coating |

Pipe Manufacturing Industry |

Steel Grit G-14,G-18,G-25 |

Pipe Manufacturing cleaning before coating |

Coating Industry |

Steel Grit G-12,G-14,G-16 |

Enamel removal |

Shipbuilding Industry |

Steel Grit G-18,G-25 |

Shipbuilding plates cleaning before painting |

Granite Industry |

Steel Grit G-16,G-18,G-25 |

Granite cutting works |

Container Manufacturing Industry |

Steel Grit G-16,G-18,G-25 |

Container Manufacturing grit sandblasting |

Tube Manufacturing Industry |

Steel Grit G-16,G-18,G-25 |

Roughening the tube surface prior to paint |

|

صفحه اصلی محصولات ما

صفحه اصلی محصولات ما در باره ما

در باره ما  رفرنس های ما

رفرنس های ما  دسترسی و ارتباط

دسترسی و ارتباط  ویدئوها

ویدئوها